Cookie notice

This websites uses analytical cookies. These are only placed as soon as you agree to them.

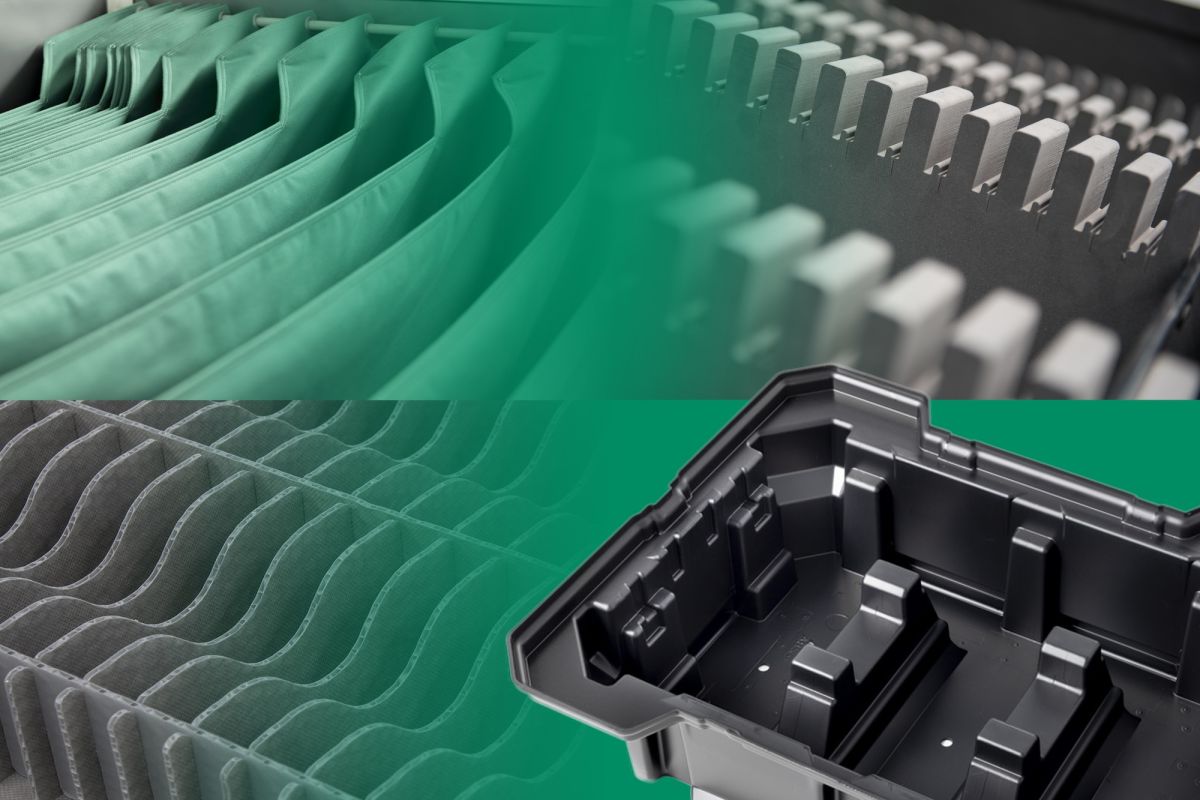

Custom dunnage inserts

Custom made dunnage for every packaging need.

Our dunnage seamlessly integrates with various large and small containers, boxes, steel racks, irrespective of their size, material or customization.

With extensive options for inserts, there’s always a solution for your challenge. Should specific demands arise, we have the capability and know-how to source or develop new materials to meet your unique requirements.

Our dividers are designed and manufactured with the safety for the operator and the part in mind. Above all they offer optimal protection to the parts that are transported.

There’s always a right solution for your specific needs

Our textile dividers are known for their optimal nesting while offering maximum protection and durability. With our extensive inventory of diverse fabrics, conTeyor ensures efficient production and global delivery on short notice.

Should specific demands arise, we have the capability to source alternative textiles or develop new ones to meet your unique requirements.

conTeyor offers foam solutions with different weights, qualities, and densities to cater to diverse packaging needs.

We are able to cut various types of inserts on our water jet machine, including angles and provide different foam densities and thickness to meet all packaging needs.

Our expertise in vacuum forming allows us to masterfully create trays that meet your exact specifications. Leveraging our extensive knowledge of raw materials such as PS, PP, PC, PVC, ABS, and HDPE, we can swiftly produce the ideal product with minimal lead time.

conTeyor specializes in the development and production of PP plastic dividers, carefully designed to meet diverse packaging requirements.

Our PP dividers are available in different material strengths and surface finishes, ensuring an optimal fit for each specific application. To enhance part protection and operator safety, we offer additional lamination and rounded top edges.

Let’s discuss your challenges

Get in touch

We have regional representatives available to assist you in your area. Select your location, and you’ll see a list of all representatives specialized in your region.