Cookie notice

This websites uses analytical cookies. These are only placed as soon as you agree to them.

News

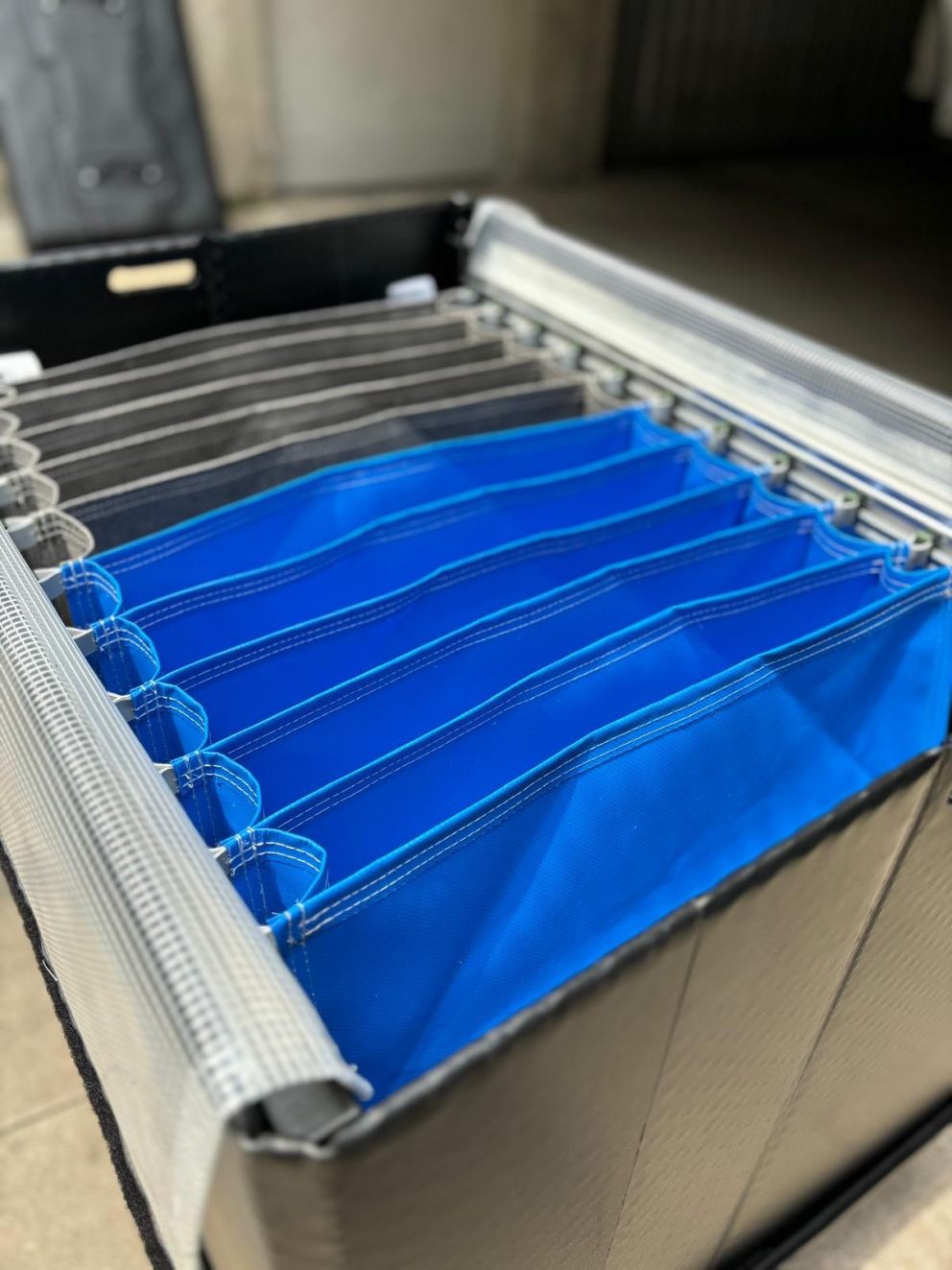

conTeyor recently developed two next generation textiles in their journey to reduce carbon footprint and to reduce the overall emissions from the usage of textile. The textiles that are developed, “NexTTex” and “EvoForce”, each realized a carbon footprint reduction of 50% and both replace PVC, to obtain a dioxin-free product. Through the development of these textiles we empower our customers to reduce and improve their environmental impact and lower their total cost of ownership.

NexTTex is made out of a 100% recyclable membrane which eliminates PolyVinylChloride (PVC) in textile bags. It’s a 100 % Polypropylene textile as strong as a PVC coated fabric and has no issues with plasticizers migration. The textile is a light weight solution – 30% lighter than PVC –but it maintains PVC’s strong features such as flexibility and high durability. The textile is perfectly UV resistance.

The production of EvoForce starts from recycled PET bottles which optimizes the closed loop model. EvoForce is a recycled and recyclable textile which is as strong as PVC coated scrim. It’s a 4-layer construction but 50% lighter than PVC and offers a premium surface part protection. EvoForce meets the criteria of eco check.

Get in touch

We have regional representatives available to assist you in your area. Select your location, and you’ll see a list of all representatives specialized in your region.